I had a look at the first three and the Festool TS55 was very impressive. However when I compared it to the Bosch GKT 55 GCE I felt the Bosch had the edge on the original.

So I took the plunge, so to speak, and raided the piggy bank to buy the Bosch.

What's In The Box?

The particular deal I went for was for the saw, an L-Boxx storage case, two plate tracks, joining plate, track clamps and plate carrying case.The delivery came in two packages, a large cardboard box containing the Saw and accessories, the other a long thin package containing the tracks in their carrying case.

The saw

The saw is very well made with a feeling of solidity that shouts "I mean business". Most of the parts are made from steel, aluminium and substantial plastics of unknown material. It weighs 4.7 kg.The base has a removable insert which allows the saw to be used on other manufacturers tracks. The blade remains covered above the cut line when performing a plunge cut.

Speed control and electronics

There is a variable speed control dial linked to the soft starting electronic drive controller. This varies the rotational speed from 3600 to 6250 rpm. The manual states different speeds for different materials using various saw blade materials.

|

| Speed control knob on the end of the motor housing. |

The trigger cannot be depressed until a safety button is slid upwards with the thumb. Also the trigger must be held in by the finger and there is no lock on feature. These are good safety features that I have seen on other Bosch Professional tools.

The electronics also control the saw should it start to overheat. It constantly monitors the current and should a bog down cause the temperature to rise it will slow the saw or stop it while it cools down.

Depth of cut

The depth of cut is controlled by a sliding scale that is moved by depressing a button and sliding it to the desired depth. There is also a rotating cursor which compensates for whether you are using the saw on the track or off the track.

|

| View showing the rotating cursor track compensator |

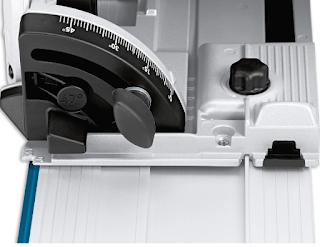

Angle adjustment

Bevel cutting is taken care of by loosening a couple of thumb screws either end of the base and rotating the body to the desired angle. There are positive click stops at 0 and 45 degrees. Another useful feature is the ability to go up to 47 degrees or -1 degrees for under/overcutting. To do this you press another button located at the end of the scales. The scale is marked in 1 degree increments with major markings every 10 degrees.

|

| Bevel angle scale. To tilt beyond 45 degrees press the 47 degree button. There is one on the other end to tilt to -1 degree. |

Attachments

Bosch have a range of different attachments for the saw system.

There is a facility to attach an edge guide should you decide not to use the track and use the saw as a regular circular saw.

|

| Edge guide |

|

| Mitre Segment |

|

| Anti kickback support |

Once you have bought into the Bosch Track system you find there are more attachments that can be used for other tools in their Professional (AKA Bosch Blue) range. For instance there is also an attachment for a jigsaw to have guided straight cuts and another which will create circle or curved cuts using the guide rail system.

I didn't buy any of these so can't really comment on their respective usage but its interesting to know they are available.

Plunge mechanism

The saw pivots in a similar way to the Festool and has a moderate force return spring to retract the business end back into the body when you have completed the cut and released pressure. This is unlike the Dewalt which has a parallelogram mechanism to enable plunging.

Power

The supplied power cord is the usual very long length that you come to expect on professional power tools. I wish DIY tools had long power cords too. The tool can be ordered with 110V or 220/230V and the cost is the same. In the UK it is fitted with a standard fused domestic 13 amp power plug for 230V or 110V yellow power plug.

Blade and blade changing

The supplied Bosch blade is 165mm diameter with a 20mm bore. The plate thickness is 1.6mm and kerf is 2.6mm max. To change the blade the saw can be laid onto the flat bottom of the motor cover. It is perfectly balanced when you do this so there is no danger of it toppling over.Blade changing itself is very similar to the Festool method:

|

| Lift the blade changing lever to expose the safety button. |

|

| Depress this button while pressing the safety button enables the blade to me pressed down |

|

| Push down the body until it locks and the blade can then be changed. |

- Flip up the blade changing lever

- Push the lock off button towards the front

- Depress the saw towards the saw base. It will engage into saw changing position with a click.

- Press the spindle lock button and keep it pressed.

- Loosen the saw clamp with the hex allen key. This is stored in the handle of the saw.

- Remove the clamping flange. The saw blade can then be extracted from the saw spindle.

- Re-assemble by reversing the process.

Tightening torque is 6 to 9 Nm which corresponds to hand tight and then 1/4 turn more.

Returning the blade changing lever back to normal position allows the saw to retract back into the body.

Dust/Chip Extraction

Connection of a 35mm vacuum hose to the chip ejector port is simple and worked well with my shop vac. The chip ejector port is made from steel and can be rotated to any desired position with a positive click locking action.

Bosch, of course, recommend the use of their own shop vac for all their machines but I found mine works just fine.

The blade shroud catches 90% of dust generated and can be increased on the non blade side by sliding down the transparent viewing window which shrouds the front of the blade. It also helps to minimize tearout on the blade side of the cut.

I'm not sure how dust collection compares to the Festool which is renowned as being superb in dust collection but my tests showed very little dust remaining on the work surface when cutting MDF.

Bosch, of course, recommend the use of their own shop vac for all their machines but I found mine works just fine.

The blade shroud catches 90% of dust generated and can be increased on the non blade side by sliding down the transparent viewing window which shrouds the front of the blade. It also helps to minimize tearout on the blade side of the cut.

|

| Sliding shroud/splinter guard used to improve dust collection on the non track side. |

I'm not sure how dust collection compares to the Festool which is renowned as being superb in dust collection but my tests showed very little dust remaining on the work surface when cutting MDF.

Guide Track

The saw has a snug fit onto the guide track and there is absolutely no play when supplied from the factory. This was unlike the Festool and Dewalt saws I tried that did have a slight amount of play. In any case those saws and indeed the Bosch saw have a couple of adjusting knobs to take up any play.The saw slides along the track with no issues at all. Maybe a little paste wax on the mating faces would make it even easier. The underside has a couple of full length rubber inserts designed to stop the track from sliding about on the work. This works really well and once positioned stays put. There is also a full length tee slot in the aluminium extrusion which takes the special clamps. These can be slid anywhere along the length of the track and are used for increased security.

|

| Track clamp |

Bosch can supply tracks in 5 lengths:

- 0.8m (31")

- 1.1m (43")

- 1.6m (63")

- 2.1m (83")

- 3.1m (122")

The tracks I opted for are 1.6m in length and these are the most popular. This allows more overhang when cutting 4 feet wide sheets. The Festool equivalent is only 1.4m (55") long which just about works but you have to plunge into the cut. The slightly longer 1.5m (59") Dewalt track almost allows pre-plunge before starting the cut. However the Bosch can be pre-plunged before the cut and follow through the entire cut.

As I had bought two tracks it came with a joining plate.

|

| Track connector joining plate |

This slides into slots on either end of the track and the two tracks brought together. Clamping is via cams actuated by either a coin or the supplied tool. This has an hex key one end and a screw driver the other end. This can be slotted into the handle replacing the hex key. I checked the tracks for alignment and it was very straight when connected. So you can cut long lengths and be sure they are straight. My tracks joined will cope with lengths of up to 3.2m. If you have more tracks I'm sure you can make them as long as you want. I did hear of one guy who had enough tracks that he could trim out the edges of boards inside a gymnasium in one go!

The ends of each track have a plastic insert which is removed when joining them together. When in place the radius on the insert allows any cable or vac hose easy passage to minimise snagging.

|

| Radiused plastic cover insert minimizes cord and vac hose snagging |

My particular deal came with the excellent track carrying case. This looks like a fishing rod carrying case in blue with Bosch Precision Wood System displayed. It has heavy duty zips running around the periphery and a zipped pocket for any attachments. There is also a shoulder strap and a couple of handles that can be locked together with a padded velcro lined linkage.

|

| Guide rail carrying case |

The tracks I'm led to believe from other users are exactly the same as the Mafell tracks. Indeed the saw may well be made in the same German factory as the Mafell. If anybody knows for sure let me know.

Guide Track Splinter Guard

This is intended to minimise splintering of stock around the cut line. The splinter guard is fitted to the track and needs tuning to the blade in use.The recommended initial cut method is to position the track on a strip of scrap stock and set the blade to protrude 1mm. Then fit the saw to the track, power up and pivot the saw into the track. Run the saw the full length of the track and power off. There will be some green dust, even when using the vacuum extract, and a length of rubber offcut. The splinter guard is then set up for the blade.

You have to repeat this if you change the blade to another plate thickness. Bosch sell splinter guards as spare parts should yours become mangled after heavy use.

|

| Replacement splinter guard |

L-Boxx

|

| L-Boxx 374 |

The L-Boxx system is not a unique concept. Indeed Festool have the Systainer system and Dewalt have the T-Stak system. In use the boxes can clip together and be transported on a dolly or wheeled truck. The L-Boxx system can also be docked into the Sortimo modular system to enable you to outfit your truck or van with a truly mobile carrying system.

My existing L-Boxx containers simply slot onto the the L-Boxx 274 making a big stack.

|

| A random internet grab of the L-Boxx system |

In use

This saw is designed for industrial applications and can be used constantly throughout the working day. It is great for a job site usage and in my particular application as a home shop wood worker.I was able to cut every type of sheet good that I could throw at it. MDF, plywood, OSB, particle board, veneered sheet goods etc all with excellent results. The cut on the track side is generally flawless with no tear out. This is due to the excellent splinter guard. On the waste side or non track side of the blade it was excellent but not absolutely flawless. If you have some boards to cut to width I suggest using masking tape or blue tape over the cut to minimize any tear out. However if you are cutting boards to size on the track side then there is no need.

When cutting bevel cuts the geometry of the saw makes the cutting edge of the blade pivot precisely around the tip of the splinter guard. You can be confident that the edge of the bevel is exactly where you place the track to cut it.

I was also able to cut up to 50mm hard wood stock, oak, sapele, iroko with no bogging down/burning as long as I took my time. In fact I wasn't aware of the cut when going through 8/4 iroko stock as it was really smooth.

One thing I should mention is there is no riving knife on this saw. I'm not sure why it has been omitted as even the most basic of regular circular saws has one. I asked why on the Bosch forum but as yet have not had a response. As I will only be using this for cutting sheets goods with the occasional cross cutting of hard wood I am not too bothered. However if you intend using this saw to rip long lengths of reaction wood then bear it in mind.

Conclusion

Tracks saws are not the game changer that they once were when Festool and the more expensive Mafell were the sole manufacturers. Now the competition is wide ranging to fit all budgets. Sure the KoolAid and Mafell offerings are still there but they are now joined with makers such as Makita, Dewalt, Grizzly, Scheppach, Triton and of course Bosch. This is not a cheap saw, is made to a very high standard with tight tolerances, quality materials and great design. I believe while there is competition from the likes of Bosch then Festool need to up their game to get people to continue to buy their saws. This Bosch GKT55 GCE is a seriously good track saw which is intended for everyday usage by demanding users. I like it very much.The kit I bought can currently (June 2016) be purchased from Axminster Tools in the UK for £438.95 including VAT and free next day shipping. There is a manufacturers 3 year warranty too. You just have to register the purchase on the Bosch Power Tools website.

Though speaking with fellow woodworkers on the WoodTalk forum I discover that the tool is not available in the USA or Canada which I find odd. However we in Europe cannot buy the very popular Dewalt DW735 thickness planer having to make do with the inferior DW733 instead.

Ces't La Vie.

(C) Terry McKnight 2016 All rights reserved.

No comments:

Post a Comment